The slag inclusion defect of lost foam casting refers to the defects formed by the liquid metal entering the casting during the pouring process of molding sand particles, coatings other inclusions. For system engineering, practical measures must be taken carefully operated in various aspects such as coating, packing operation, pouring, negative pressure, slag collection slag removal slag skimming, molten iron purification technology to achieve better results.

1. Slag inclusion defects in lost foam casting:

Common casting defects in lost foam casting include sticky sand, wrinkled skin, carbon black, cold partition, collapse box, pores, slag inclusion, deformation, carbon leakage on the surface of steel castings, etc. Slag inclusion defects refer to dry sand, paint Others, on the surface of the machined castings, you can see spots of white black-gray inclusions, distributed individually in pieces. The white is quartz sand particles. The black defect is commonly known as "sand", which is used in the production of lost foam casting It is widespread difficult to eradicate completely. A variety of measures careful operation can only achieve better results.

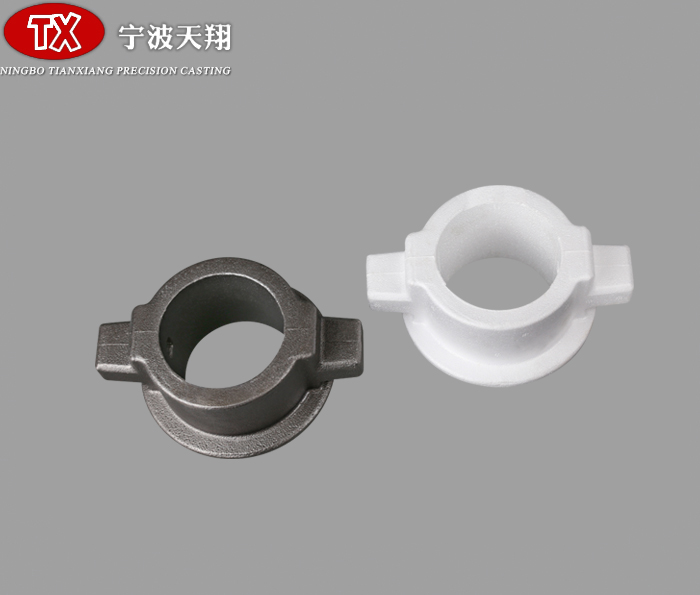

After the lost foam castings are cooled boxed before being cleaned, according to the surface conditions of the castings the pouring system, it can be judged whether there are sand slag inclusion defects. If the sprue cup, sprue, cross sprue, sprue gate surface connection, the surface of the casting are severely sanded have cracked sand, it is basically certain that the casting has sand slag inclusion defects. Smash the sprue rod sprue bead, you can see white spots on the fracture, in severe cases, the fracture forms a circle of white spots. At this time, castings, especially plate-shaped round-cake-shaped castings, will have white black-gray spots on the processing surface after machining. Automobile engine clutch pressure plate other castings are the most easy to enter sand, which seriously affects the quality of castings production schedule.

2. Causes of sand slag inclusion defects

Production practice has proved that the sprue cup, the sprue, the sprue, the runner, the inner runner to the casting, all parts may cause sand ingress, especially the bonding part. In the whole production process, the paint peeling cracking on the surface of the white mold of the gating system, the paint peeling cracking at the bonding part of the white mold, the paint peeling cracking on the surface of the white mold of the casting, the sprue is tightly closed other factors are caused by the defects of sand slag inclusion. The main reason. Secondly, the selection of process parameters, such as pouring head size, pouring temperature, negative pressure, dry sand particle size, etc., as well as the model transportation process packing operation, all have a great impact on the casting sand slag defects. influences. Only by adopting systematic measures careful operation in these links can we reduce eradicate slag inclusion defects obtain high-quality castings. Overcoming the defects of slag inclusion is a systematic project.