In 1947, the British Morrogh (MorroghJH) first discovered cerium-containing ductile iron. Gagnebin used Mg to obtain nodular graphite as-cast cast iron, which paved the way for the development of contemporary ductile iron. Nodular cast iron is used to produce crankshafts, nuclear fuel waste storage tanks, etc., is widely used in machinery manufacturing, metallurgical mines, petrochemicals, transportation other functional departments. Spheroidization solution inoculation solution is an important link in the production process of nodular cast iron. The purpose of inoculation solution for spheroidal graphite cast iron is to eliminate the whitening tendency of nodular cast iron, eliminate undercooled graphite, promote graphitization, refine eutectic clusters Reduce intergranular segregation, etc. This article mainly introduces the spheroidization of nodular cast iron in the world the scientific research of its incubation solution: expounds on the basis of alloying. After the rare earth silicon spheroidizing agent are added at the same time, ordinary inoculation is the key method for the production of as-cast thin-walled new ductile iron, in-mold inoculation is the key method for producing Y-shaped high-strength ductile iron castings in the as-cast state.

1 Research status of cast iron spheroidization its inoculation

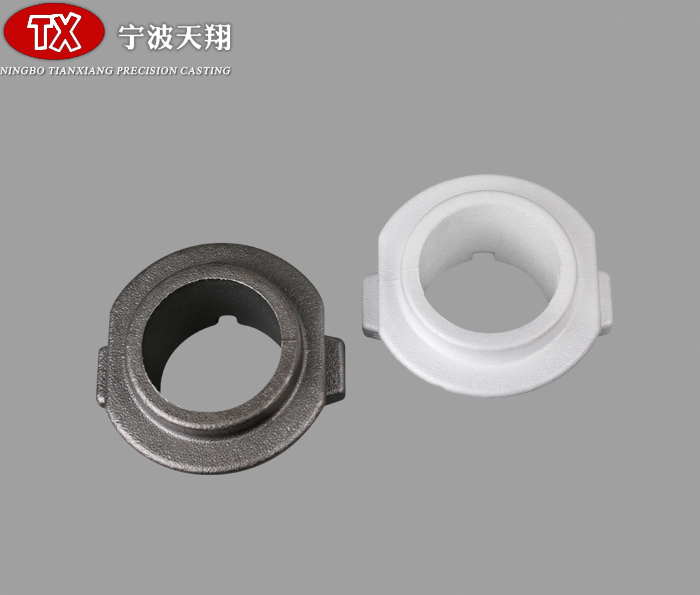

Nodular cast iron refers to adding a certain amount of spheroidizing agent inoculant to the molten iron, which can be solved by spheroidization inoculation to make the carbon nucleate grow in the form of nodular graphite when the molten iron is solidified. After solidification, the structure of the cast iron can obtain nodular graphite. cast iron. Spheroidization solution inoculation solution are important links in the production of nodular cast iron.

In terms of spheroidization solution technology. At this stage, the main solutions to spheroidization in various countries in the world are: ladle punching spheroidization method, cap ladle method, pressure adding magnesium method, magnesium coke method, GF subcontracting method, airtight flow method, internal spheroidization solution, etc. 12-31. Among them, the most commonly used method is the ladle spheroidization method, which has the advantage of simple actual operation relatively stable manufacturing. However, this type of solution has the disadvantages of low absorption capacity of the spheroidizing agent magnesium, deterioration of working conditions due to the massive combustion of magnesium during the spheroidizing solution. In order to better overcome many shortcomings, the capping method, the pressure adding magnesium method, the magnesium coke method, the GF subcontracting method, the airtight flow method, the solution of internal spheroidization were followed. At this stage, the GF subcontracting method the covering method are widely used overseas, they are also being promoted in China. In terms of spheroidizing agent, the commonly used spheroidizing agents in various countries in the world mainly include rare earth magnesium ferrosilicon alloy, calcium magnesium spheroidizing agent, nickel-magnesium alloy spheroidizing agent, magnesium alloy pure magnesium alloy. Among them, rare earth magnesium silicon is more commonly used. ferroalloy. In the domestic production manufacture of "Hot Working Technology" 2008 Vol. 37 No. 13, 1.25 million cubic meters of data Metal casting, forging welding technology | Casting·Forging·Welding in July 2008, the spheroidizing agent commonly used is rare earth magnesium alloy, many overseas Due to the lack of rare earth resources in the country, most of them choose magnesium alloy pure magnesium. For example, the spheroidizing agent mainly used in Japan is calcium magnesium cerium spheroidizing agent. Nickel-magnesium alloy spheroidizing agent is mainly used in the American continent Europe. This type of spheroidizing agent is relatively expensive is basically used in China.

In the research of graphite material spheroidization theory, the spheroidization theories models that have been pointed out mainly include: iron carbide rapid decomposition theory, supersaturated austenite theory, bubble theory models, sulfide other graphite material sphere core theory, Graphite material sphere growth theory such as supercooling theory, adsorption theory, surface energy theory, dislocation theory model. The main point of the iron carbide rapid decomposition theory is that the carbide is solidified first, then the carbide is resolved into the graphite material; the main point of the supersaturated austenite theory is that the graphite material is directly precipitated the molten iron then surrounded by austenite. Carbon grows into a spherical shape through austenite diffusion: The main point of bubble theory model is that carbon atoms diffuse inward into a spherical core in the tiny bubbles of magnesium vapor. Then it grows into a spherical shape along the core. This theory is denied by Davis. The main point of the core theory is to directly observe the core substances of graphite materials through electron microscope. These substances include sulfides, oxides, Mg-Si compounds, etc., then advocate Such tiny substances in liquid form are the core of spherical graphite materials: at this stage, it seems that core theories such as sulfides are the accepted theory of spheroidization nucleation of graphite materials, but it also cannot answer the question of how graphite materials grow into spherical shapes. The main point of the supercooling theory is that the graphite material core disappears due to the addition of magnesium, the growth rate difference of the graphite material along the a-axis c-axis directions in the supercooled state is reduced. As a result, the graphite material grows into a spherical shape instead of a flake shape: the main point of adsorption theory In order for magnesium to be adsorbed on the graphite material, the surface tension of the graphite material is increased to make it spherical; the main point of the surface energy theory is that the added magnesium other spheroidizing elements in the molten iron reduce the activity of sulfur, the surface of the graphite material the molten iron The energy becomes larger, the interface area between the two shrinks into a spherical shape: The main point of dislocation theory model is that the spherical graphite material grows into a spherical shape along the screw dislocation. So far, no conclusions have been drawn on the spheroidization theory of graphite materials. Based on previous spheroidization theories their research results, Nakae Hideo others believe that the sulfides of elements such as magnesium cerium in the liquid phase of ductile iron form the core of graphite materials. In the growth process, it becomes spherical. When the eutectic solidification starts, the graphite material is surrounded by austenite, the carbon element grows through the solid phase diffusion of austenite. At the same time, it points out the extreme importance of increasing the number of graphite balls.

Inoculation treatment is one of the key steps in the production of ductile cast iron. The so-called inoculation treatment means that a little special inoculant is added to the cast iron solution to promote graphitization, avoid the formation of cementite, refine the structure, improve material mechanics performance. At this stage, the inoculation treatment methods mainly include ladle inoculation, liquid inoculation, inoculation silk inoculation, instantaneous external inoculation, intramolecular inoculation. Ladle inoculation is one-time inoculation is a method widely used by many domestic manufacturers. Liquid inoculation belongs to two inoculation methods of liquid iron blending. Used for the treatment of large medium-sized cast iron parts: the inoculation wire is a hollow steel wire with powdery inoculant, the inoculation process is carried out in the sprue. Inoculation treatment can be divided into primary inoculation secondary inoculation. Previously, it was mainly one pregnancy. There are many defects in one inoculation, such as the added inoculation dose is large, the other defect is the phenomenon of inoculation decline. In recent years, countries around the world have developed many secondary inoculations their instant inoculation treatments. The main specific methods are: inverted ladle inoculation, sprue cup inoculation, ladle funnel inoculation in-mold inoculation, etc. Breeding in its medium type is a specific method for the treatment of the actual effect of the current stage. It was first studied in 1968, it was developed used in Europe in the early stage. After that, the United Kingdom, the United States, Canada other countries just started to apply for patents. At this stage, countries with relatively developed industrial production have just begun to use it, especially overseas in the casting of engines diesel engines the inoculation treatment of thin-walled high-strength gray cast iron. In our country, it is relatively slow to promote research on inoculation treatment technology.

Regarding inoculants, the main types of inoculants that are common at home abroad at this stage are Si-Fe Fe-Si. Ca, Si. Ba. Ca, RE. Si, Ce series, Ba series, Ca series, graphite series, Fe-si. Sr et al. Among them, the economical convenient inoculant is silicon inoculant. For example, most domestic use ferrosilicon with a mass fraction of 75% silicon, the actual effect of pure silicon inoculation is very poor, overseas usually contain 2.5% calcium aluminum. In recent years, there has been a lot of research on inoculants overseas. Many people add a certain amount of other alloying elements to silicon to get a higher practical effect of inoculation, in which Fe. Si. Ca, Si-Ba. Ca inoculant is suitable for low-sulfur molten iron high-sulfur molten iron, has the function of improving tensile strength reducing the tendency of white mouth; RE. Si, Ba series Ca series inoculants are suitable for low-sulfur molten iron, also have the functions of the former Fe. Si. Ca. Al-Ba is used as an inoculant within the type.

In the study of the inoculation mechanism of ductile iron. Inoculation theory model mainly have the following aspects: Carbide core theory. The main ones are A13C4 graphite core, CaC2 core SiC2 core. The carbide core theory states that the effective elements in the inoculant react with the carbon in the molten iron to produce carbides as the graphite core. However, this theory was replaced by the later Fe-Si crystallization inoculation theory: oxide theory, which pointed out that the silicon element in the inoculant reacts with molten iron to produce silicate particles as the core of graphite, but this theory cannot explain the decline phenomenon other unique phenomena of incubation: homogeneous crystal nucleus theory, homogeneous crystal nucleus theory points out after incubation. When silicon dissolves diffuses, a graphite core is formed at the part of carbon supersaturation; the undulating nucleation theory, which points out that the inoculant produces many microscopic concentration fluctuations temperature fluctuations in the molten iron, then produces many graphite crystals. HotWorkingTechnology2008, V01. 37, No. Casting-Forging·Welding|The core of metal casting-forging welding technology was published in the first half of 13th. This "fluctuation nucleation theory" is one of the most representative theories at this stage: the sulfide theory, which points out that in flake graphite cast iron, By adding a chemical equivalent of RE elements, a composite sulfide of RE Mn, which acts as the core of graphite, is produced, thereby promoting graphitization. In ductile iron, the sulfides of cerium magnesium are used as the core of spheroidal graphite, increasing the number of graphite spheres to promote graphite It is one of the new inoculation mechanisms of rare earth inoculants at this stage. Fe. Si crystallization inoculation theory, the theory believes that the inoculant is added to the cast iron solution. The Si in the inoculant is oxidized to produce amorphous SiO: the trace element Ca in the inoculant acts as a catalyst to crystallize SiO. This crystallized SiO: acts as the core of graphite. Use this The theory denies CaC: the theory, it is also one of the new birth theories.

发送反馈

历史记录